If you understand something in regards to the sensible aspect of creating watches, you understand that manufacturing is a delicate matter. You would possibly, for instance, see information about some huge new construction that watchmaker A is constructing, and naturally marvel what number of extra watches might be made below that roof. Now, if you understand a bit extra about watchmaking, it is not going to shock you to study that extra watches should not on the playing cards – not less than not immediately, however definitely by no means to the extent that manufacturing will instantly double.

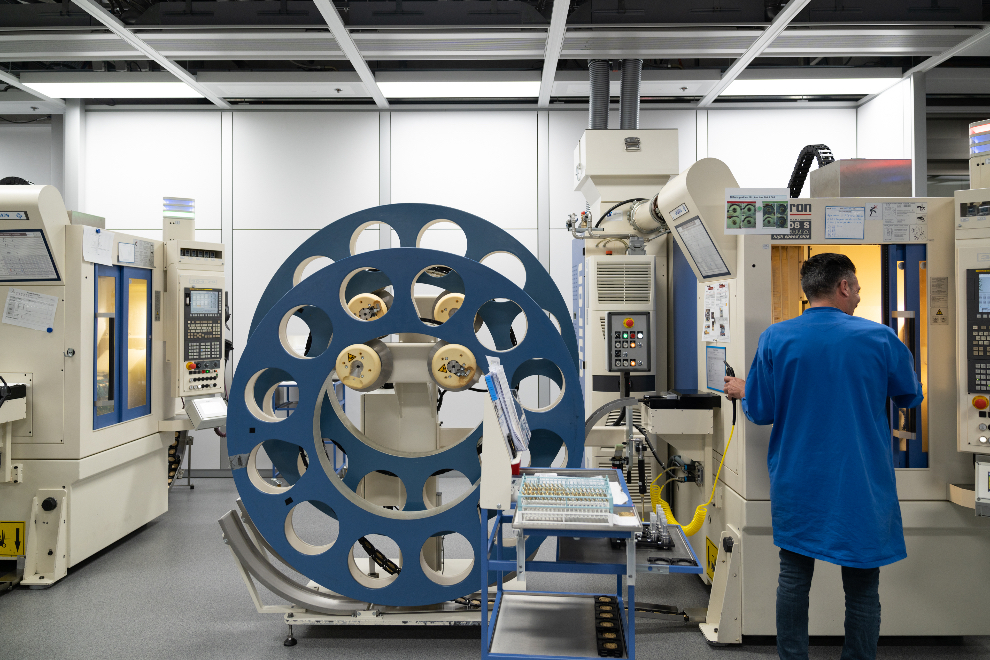

Whereas visiting the brand new Patek Philippe facility in Geneva’s Plan-les-Ouates neighbourhood (affectionately generally known as Plan-les-Watches or Plan-les-Watch), we’re proven a staggering variety of CNC (laptop numerical management) machines. It was actually a show-stopping second for the press tour, organised for Southeast Asia media, particularly for these of us who understood that CNC machines can run 24/7. For a second, this author thought-about simply what number of brass motion blanks could possibly be produced on the new PP6 facility with the multi-axis CNC machines. That silly second handed shortly although as a result of Patek Phlippe helpfully knowledgeable us that gears, pinions and arbours (additionally produced right here, with completely different CNC machines in a course of known as bar-turning, the place the uncooked materials bars flip however the instruments are fastened) wanted to be completed by hand. Something with tooth, actually. To be blunt right here, this actually signifies that each spoke of each wheel will get some particular person consideration, nonetheless miniscule it is likely to be.

Pulling again a bit from this particular close-up, the truth of watch manufactures is commonly shocking as a result of these websites are sometimes large – the brand new facility we visited stands 34m excessive, with 10 storeys (4 are underground, which Patek Philippe actually describes as subterranean, in good previous secret lair fashion) for a complete of 133,650sqm. Clearly, the location is huge but Patek Philippe’s manufacturing quantity of 70,000 watches (that’s the top-end estimate; Patek Philippe doesn’t disclose particular manufacturing numbers). What’s required right here is an establishing scene, so allow us to take you again to 2019, within the Earlier than-Instances – allow us to return even additional than this, for a little bit of context.

In The Starting…

Patek Philippe has been on mission to broaden and improve its capabilities because the agency got here to life in 1839, and positively because the Stern household took over within the 1930s. In all this time, wealth has change into extra democratised, and timepieces discovered themselves on the wrists of extra folks than ever earlier than. Bear this in thoughts once you go to the Patek Philippe Salons in Geneva – one in every of three owned and operated by the model itself – as a result of this area used to accommodate the watchmakers. When the arrival of quartz expertise put paid to many a storied identify, and even despatched the watchmaking commerce into decline, these corporations that soldiered on – Patek Philippe amongst them – discovered that they needed to take steps to guard your entire business. As a matter of truth, the Patek Philippe Museum occupies an area previously utilized by one in every of its suppliers, now turned in-house division – the famed bracelet-maker Ateliers Reunis. Whereas each Salons and Museum are spectacular, they can’t examine with the newest addition to Patek Philippe’s manufacturing amenities.

By the point Thierry Stern succeeded as President of Patek Philippe, he was constructing on the work of his predecessor, his father Philippe. The elder Stern had introduced the constructing of a producing web site at Plan-les-Ouates in 1996, and that was prepared by the point the youthful Stern took over in 2009. To make an extended story considerably shorter, Patek Philippe determined that much more workspace was wanted, however had to slot in the present footprint of web site; the present amenities have been modern however merely not holding tempo with future wants. The answer unfolded in a number of levels, and work on the constructing generally known as PP6 (the topic of this story) started in earnest in 2015. Clearly, Thierry Stern needed one thing large, and PP6 matches the invoice. Whereas this itself is a superb story, we’re extra eager about what would possibly enlighten collectors and people nonetheless ready for his or her shot at a Patek Philippe watch.

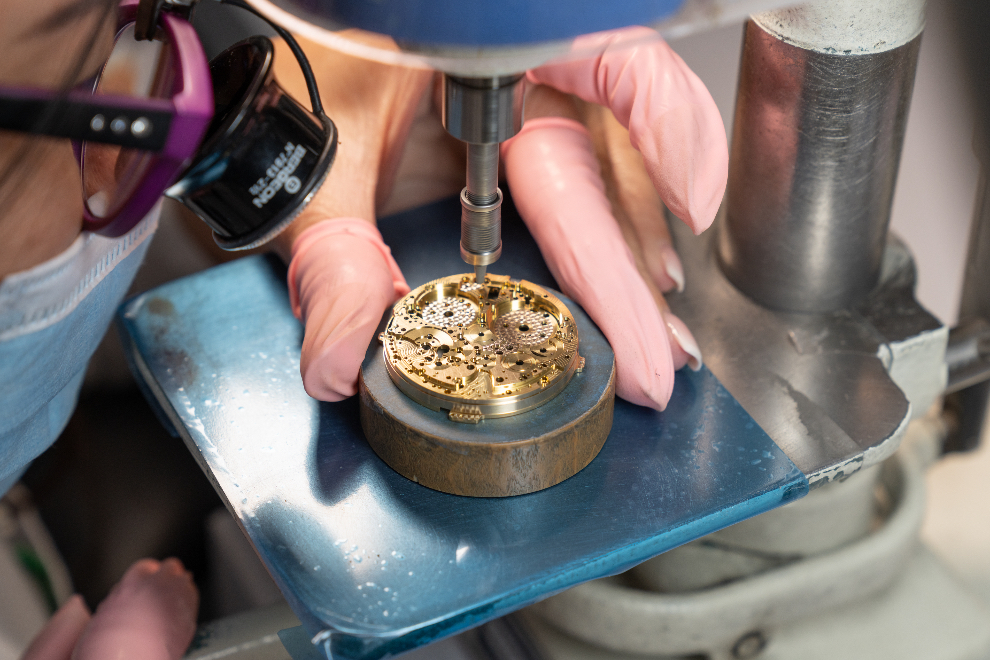

Returning to the CNC machines and the shaping of elements with tooth, that is really the place one can study one thing fascinating and presumably particular to Patek Philippe. Not singularly distinctive as a result of the manufacture is the best and finest or no matter however only a rational methodology of working that the Geneva model has adopted. The gist of it’s this: the bottom plates made right here should not meant for classy actions, however the elements with tooth are shared between all forms of calibres. Totally different machines produce plates and bridges for classy watches. Why ought to this be so? The clarification given, and what we all know ourselves, is that difficult actions elements, together with plates and bridges, are thicker than regular. These are filed all the way down to the suitable dimensions (nonetheless thicker than normal actions) as a result of the expert palms of a craftsperson can deal with extra complicated and delicate actions than even CNC machines can.

Labored By Hand

The tourbillon bridge is a superb and generally used instance, as a result of the tough half is labored over by hand fairly intensely. Further materials additionally helps ameliorate minor errors, that are inevitable. Gears and pinions, however, may be made to 1 normal specification. Not that any model discusses issues like errors however they do occur as a result of in the event you take off an excessive amount of whereas bevelling, for instance, there isn’t a going again; this author is aware of that from expertise, on condition that tolerances listed here are past what the bare eye can apprehend. Suffice to say right here that those that are on the lookout for the reason why Patek Philippe is likely to be production-limited – even with automated processes within the combine – can discover one essential level within the hobbing course of, and what follows after. Hobbing is the technical time period for the manufacturing of tooth on elements.

Sadly, space-constraints restrict us as a lot as they do a watchmaker similar to Patek Philippe, so we should transfer on for a bit bit to bracelets and metiers d’artwork. We might have beloved to inform you extra about motion meeting however that was not on the playing cards on this event, and this operation really takes place in one other constructing right here on the Plan-les-Ouates manufacture. On that observe, we might be remiss to not point out the Superior Analysis division at Patek Philippe, which is on the third ground of PP6. Sadly, this was not a part of the tour this time, though we maintain out some hope that it is going to be in future. Having a purpose to return to the Patek Philippe manufacture isn’t any purpose to complain.

And so, on to bracelets we go, and this one might be standard with the broader watch fanatic world. After all, the bracelets we noticed in manufacturing have been for the. Nautilus, which is likely to be tied for many unique and most well-known watch bracelet on the earth – the GOATs of bracelets, one would possibly say. It’s at all times superb to see bracelets taking form, hyperlink by hyperlink, though it have to be stated that the uncooked materials right here arrives within the type of a bar that’s within the tough dimensions required (full with a groove within the center). Famously, there are 55 steps concerned in making the Nautilus bracelet, and Patek Philippe did put aside fairly a little bit of time to get into this. Now, you would possibly marvel why all of the fuss over bracelets however of all of the manufactures we visited this 12 months, Patek Philippe is alone in displaying the world the way it makes its bracelets in its personal manufacture. Certainly, most watch manufacturers outsource the manufacturing of bracelets to a specialist, however Patek Philippe acquired its personal provider a few years in the past (as famous briefly above).

Case Examine

To proceed with the making of bracelets, the formed bars are despatched into the bar-fed machining centre to type particular person hyperlinks. This can be a milling course of, to maintain issues succinct, and entails many quality-control steps in addition to hand-correction, however these should not a part of the 55 steps. As you understand, there are two principal elements to the bracelet hyperlinks – the H-shaped bit and the centre hyperlink – and these are individually labored earlier than being assembled (with pins). Even after being assembled, there may be nonetheless buffing and chamfering to be finished, and the centre hyperlinks are literally polished additional to realize the signature mirror sharpening. That is finished by defending the H-links with perforated masking tape and sharpening the size of the assembled bracelet.

Shifting on to case-making, we now have nearly sufficient area to get into one other well-known Patek Philippe signature, the hobnail case- center ornament (which additionally seems on bezels typically). This can be a Clous de Paris guilloche method finished with a hand operated comb and aircraft lathe. You’ll have to think about the method required to take care of the correct amount of stress right here (the half strikes whereas the lathe stays nonetheless). On the making of the circumstances themselves, that is fairly straight-forward, with bar-turning (simply as motion elements are made), milling, stamping and sharpening within the combine. We observe for the report that Patek Philippe can be amongst the few watchmaking corporations that produce their very own circumstances, and have invested closely to carry this know-how in-house.

Lastly, we are going to spare the final phrase for Uncommon Handcrafts, despite the fact that it means we should go away issues prematurely right here and have only a phrase or two left for gem-setting in captions. Our tour included an indication of champleve enamelling, which is just one of 12 methods that every one enamellers at Patek Philippe are proficient with. The champleve method entails portray contained in the strains, that are principally cavities carved right into a dial, and this method is especially suited to letting fans have a go, as you possibly can see right here.

An indication of all methods would both be cursory or take days (in the event you visited the Grand Exhibition [in Tokyo or in Singapore in 2019], this a part of the tour is a bit like that section), and one should keep in mind that Patek Philippe additionally has different artisans engaged on dials at specialist dialmaker Cadrans Fluckiger in St. Imier. It additionally engages exterior specialists similar to Anita Porchet, whom a few of you should have met or seen in motion in Singapore, whereas additionally permitting different artisans to earn a living from home on their very own machines.

On that observe, the Patek Philippe manufacture is a form of residence for watches, the place they’re lovingly ready to be despatched out into the world. Spare a thought for this the following time you take a look at your individual Patek Philippe as a result of somebody at residence in Geneva is making an attempt to think about you discovering immense pleasure in stated watch. If a Patek Philippe continues to be in your horizon, we hope this story performs its half in convincing you that it’s price inching in direction of that imaginary line.

This text first appeared on WOW’s Legacy 2024 problem

For extra on the newest in watch reads, click on right here.